The dream of every small business is to gain a vital competitive advantage (and improve their services) in order to bring in and keep happy customers. However, figuring out how to achieve it can be nightmare.

‘Kaizen’ is one interesting solution. It’s a concept of achieving continuous improvement, and it’s caught on like wildfire among companies such as governments, major banks, and even online game developers. By adapting the principles to your own business, you can improve productivity, cut costs, and enhance your customer’s experience.

In this piece, we’ll look at what kaizen is, then look at five areas where you can adapt it to your own business. Let’s get started!

What Kaizen Is (and Why It’s Awesome)

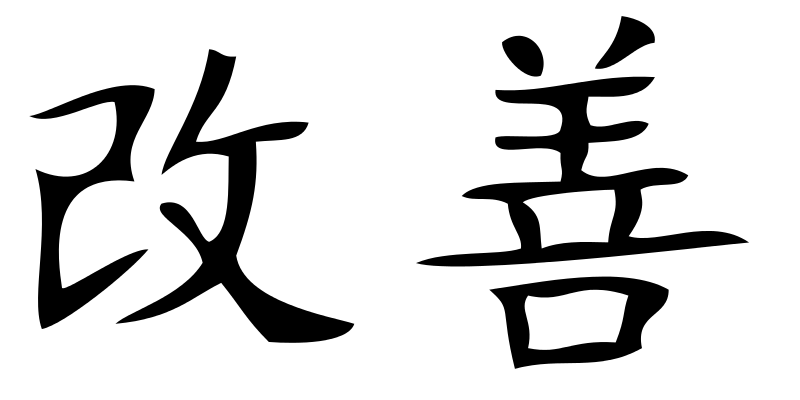

Kaizen is Japanese in origin (in case you hadn’t guessed). It’s a philosophy introduced after the Second World War, partly influenced by American business experts who visited the country, and spearheaded by car giant Toyota. It’s roughly translated as “improvement”, although in the world of business it has come to signify “continuous improvement”.

The concept (and beauty) of kaizen is that you make changes to your processes in small, achievable steps. Rather than look at business performance every year, as is traditional, kaizen means looking at it on a continuous basis.

Overall, it’s an easily adaptable concept that can increase your business’ growth. Let’s take a look at how to use it.

5 Areas Where Your Business Can Benefit Massively from ‘Kaizen’

Kaizen is a simple concept that can afford you large gains in both the short- and long-term, and getting started is simple. Below, we’ve highlighted five areas where your business can use kaizen to achieve amazing changes.

1. Management Performance

Firstly, management need to buy in to the concept for it to succeed, and ‘management kaizen’ can also be used to give their performance a boost. One initial step is to encourage managers to dedicate 15 minutes a day to making kaizen work. To that end, there are some basic principles to take on board:

- Keep asking “Why?” until you get to the root cause of a problem. Managers can use this technique to identify what’s really happening when issues arise.

- Don’t wait for perfection; a small improvement is better than none. Ensuring that managers understand it’s not necessary to embark on a months-long grand plan will free their creativity to work on practical, immediate issues.

- Data and facts matter more than opinions. So managers could, for example, create checks to ensure that all data is current, and all communications and strategies are solidly founded on facts.

- Work as a team to contain and correct the root causes of problems. This means strengthening communications between your management team and all workers so that the right people always know about any issues, and the team is involved in finding solutions.

When you’ve firmly embedded these principles you can begin to look further afield for improvements, starting with your employees.

2. Employee Performance

Kaizen means all input is valued, and you need to ensure everyone in the company (including the ‘lowly’ cleaners, janitors, and supply chain) has a voice – that’s ’employee kaizen’. It’s also true that if you want your employees to perform well, they have to find their jobs satisfying and interesting. Naturally, making them aware their thoughts are valued and ditching the blame culture is helpful to everyone.

The idea is to respect everyone’s opinions and ask for input – after all, even your cleaner may have thoughts on a better, more efficient cleaning system. This can be achieved either through a suggestion system, or in small or large groups, depending on what works for your company and the way your expertise is divided up.

Ultimately, everyone who works for you should understand their own ‘niche’, and should be encouraged to examine processes and practices to see where they can be improved. Stressing the small improvements philosophy means people don’t get overawed or put off by the enormity of finding major changes to make.

3. Management-Employee Interaction

Kaizen is also about making improvements in the way that management and employees communicate and work together. Some ‘communication kaizen’ comes naturally with the actions outlined above, because if you’re seeking your employees’ views, you’re naturally stepping up interaction.

It promotes the idea that the management are partners who help employees to develop and improve. Everyone is seen as working with each other, eliminating the old ‘boss-servant’ relationship. It makes good business sense – if management talk to employees about their duties on an equal footing, it will encourage and identify better ways of working.

It’s also here that you should ask management to actively develop work relationships with staff, and try to understand what they’re doing day-to-day. Even something as simple as greeting colleagues and asking how things are going will not only strengthen interaction, but will also help you understand what’s going on at the grass roots level of the business.

4. Productivity and Processes

Improvements in management-employee interaction naturally leads to productivity – or ‘process kaizen’ – which aims to create improvements that can be put into place on the same day. Essentially, this is a review of your activities to determine whether you can work better or more efficiently.

To use process kaizen in your own business, start with the “Plan-Do-Check-Act” (PDCA) cycle – an iterative, cyclical four-step management process:

- Plan: This means identifying an opportunity and planning a change, with management and staff working together to understand possible action areas.

- Do: This involves carrying out a small-scale trial to determine whether the change is viable.

- Check: Essentially your review stage, where you analyze the results and the lessons learned.

- Act: This depends on what you’ve learned – if the change was successful it can be incorporated into the system involved. If it wasn’t, you can start again with a different focus or approach.

If this cycle reveals a particular area where major change is needed, you can have a ‘kaizen blitz’ focusing on one aspect of what the company does for a short period, and brainstorming ways to improve it. The aim is to have fewer errors and delays, and fewer duplicated processes.

5. Customer Experience

The ultimate goal of kaizen, naturally, is to improve customer satisfaction. Inefficient business processes could potentially lead to customer dissatisfaction, so simplifying them is an important way to help improve the customer relationship.

To achieve good ‘customer kaizen’, you need to map each business phase that involves the customer in detail. This will let you identify where problems, complexity, bottlenecks, and roadblocks may occur. For example, you could check whether your purchase system on your website works smoothly, and identify small ways to improve it.

Once you have a list of potential issues, you can start redesigning the process itself using the guidance outlined here to rectify any problems. Following a test and review process, you can finally implement any good changes in line with the PDCA cycle.

Conclusion

The philosophy of kaizen is popular for a good reason – it works! It gives businesses of all sizes some great principles for organizing small, incremental improvements, and getting staff to buy-in. This may not seem like much, but when you get to the end of a year and look back, you’ll be amazed at how far you’ve come.

In this piece, we’ve outlined five basics of kaizen for small businesses, which are:

- Management kaizen: This can boost management performance and identify the root causes of problems.

- Employee kaizen: It can increase employee satisfaction and involvement in your business.

- Communication kaizen: It can facilitate management-employee interactions, and provide a deeper understanding of how your business is working.

- Process kaizen: This can be used to test and introduce proposed improvements.

- Customer kaizen: This can help to streamline business processes and improve the customer’s experience.

Do you have any thoughts about applying kaizen in your own business? Let us know in the comments section below!

Photo credit: Majo statt Senf.